Capabilities and Services

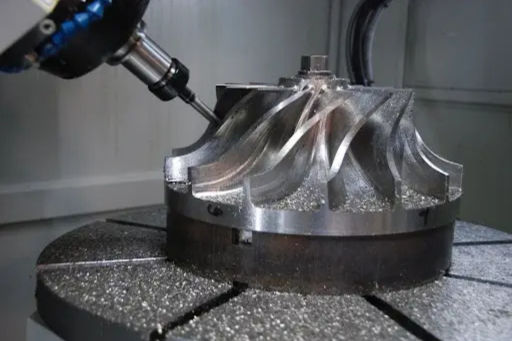

CNC Machining

We manufacture high-precision components for commercial and defense aviation. From structural parts to high-tolerance brackets, our aerospace-grade machining supports OEMs and Tier-1 suppliers with reliable and traceable manufacturing solutions.

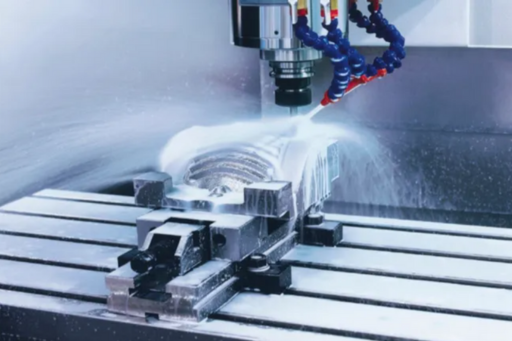

VMC Machining

Our Vertical Machining Centers (VMCs) are equipped to handle precision milling, drilling, boring, and tapping. Ideal for critical components, our VMC services are perfect for aerospace, defense, automotive, and other precision-reliant industries

Tool Room Operations

With a dedicated tool room facility, we manufacture jigs, fixtures, dies, and specialized tooling required for custom applications. Our expert toolmakers ensure reliability and performance in every tool we create.

Prototype to Production

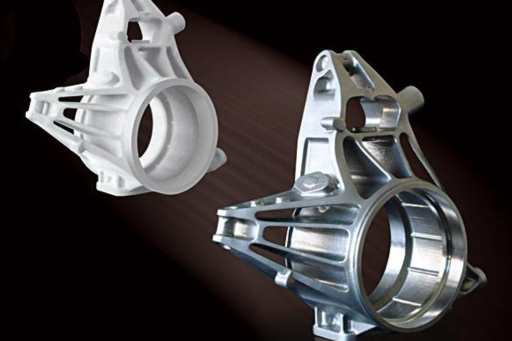

Whether it’s a one-off prototype or a full production run, we offer end-to-end support including design validation, machining, inspection, and timely delivery.

Quality Assurance

Every part undergoes stringent quality checks using calibrated instruments such as Verniers, Micrometers, Height Gauges, Bore Gauges, and CMMs (Coordinate Measuring Machines). We follow international quality standards as part of our ISO 9001:2015 commitment.

Additional Services

Machine Repairs

Count on our expert technicians to provide timely and efficient repairs for your industrial machines. We understand the importance of minimizing downtime and ensuring your operations run smoothly.

Custom Solutions

Looking for tailored industrial machine solutions? Our team specializes in designing and implementing custom machinery to meet your specific requirements. Let us bring your ideas to life.

Maintenance Services

Ensure the longevity and performance of your equipment with our comprehensive maintenance services. Scheduled inspections and preventive maintenance plans will keep your machines operating at peak efficiency.

Reverse Engineering

We offer advanced reverse engineering services using precision measuring tools and software. This enables us to recreate or improve existing parts where documentation is unavailable or design upgrades are needed.

Our Services

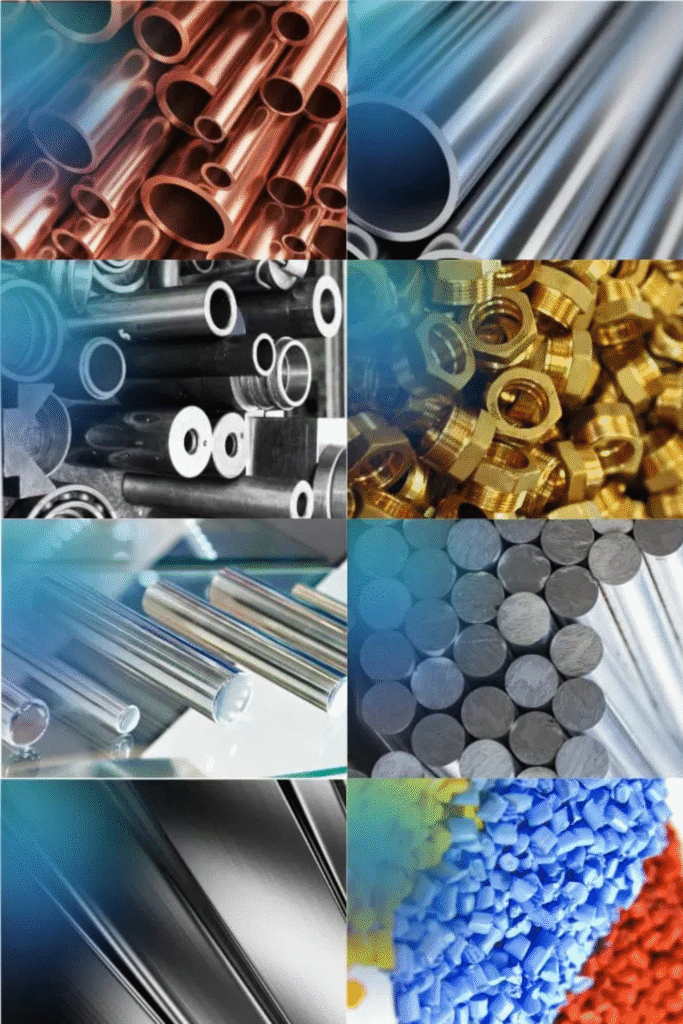

Raw Material Sourcing

At Srinivasa Machines and Tools, we understand that quality begins at the source. Our raw material sourcing strategy is built on reliability, compliance, and traceability. We partner with certified suppliers to ensure every metal grade we procure meets the stringent requirements of the industries we serve

Metals We Source

We procure a wide range of industrial-grade metals in various forms such as billets, bars, rounds, flats, blocks, and forgings. Our commonly sourced materials inc

- Aluminum Alloys

- Mild Steel & Carbon Steel

- Stainless Steel

- Tool Steels

- Alloy Steels

- Copper, Brass, and Bronze

- Titanium & Inconel

Precision Machining Services

At Srinivasa Machines and Tools, precision is not just a capability—it’s our core strength. We specialize in high-accuracy CNC and conventional machining services that deliver tight tolerances, superior surface finishes, and consistent repeatability. Our facility is equipped with state-of-the-art machinery and skilled technicians, enabling us to cater to a wide range of industries including Automotive, Aerospace, Oil & Gas, Renewable Energy, Earthmoving, and more.

Our Core Precision Machining Capabilities

Our full-cycle engineering services are designed to reduce your lead times, ensure reliability, and deliver performance across every engagement.

CNC Milling (3-Axis & 4-Axis)

We perform high-speed CNC milling operations on aluminum, steel, stainless steel, and exotic alloys.

- Ideal for: Housings, flanges, jigs, fixtures, brackets, die blocks

CNC Turning

Our CNC lathes deliver accurate and smooth cylindrical components with tight dimensional tolerances. Equipped with live tooling for milling and drilling operations on the same setup.

- Ideal for: Shafts, pins, spindles, threaded parts, bushings

Surface Grinding

We offer precision flat surface grinding with controlled surface finish and parallelism.

- Ideal for: Tooling plates, guide blocks, wear parts

Cylindrical Grinding

High-precision OD and ID grinding services to achieve roundness and concentricity within microns.

- Ideal for: Shafts, rollers, sleeves, bushes

Drilling, Tapping & Boring

Accurate hole-making operations with depth control and thread integrity maintained for all grades of materials.

- Ideal for: Engine parts, flanges, manifolds, castings

Slotting & Keyway Cutting

Precision internal and external keyways for shafts, couplings, and pulleys with guaranteed alignment.

- Ideal for: Gearbox parts, power transmission components.

Value-Added Services

In addition to core machining, we provide several complementary services to deliver complete, ready-to-assemble components:

✅ CAD/CAM Programming

3D toolpath simulation using advanced CAM software

DFM (Design for Manufacturability) support for cost-effective machining

✅Assembly & Sub-Assembly

Mechanical assembly of machined parts with fasteners, bearings, and seals

Functional testing (if required by customer)

✅ Deburring & Surface Finishing

Manual deburring, edge rounding, bead blasting, polishing, etc.

Surface finishes as per Ra specification

✅ Prototype Development

One-off and short-batch prototyping for R&D or product validation

Quick turnaround support

✅ Fixture & Tooling Manufacturing

Custom fixtures, clamps, and tooling for OEMs and job shop support

Precision-built to design specifications

Special Processes

At Srinivasa Machines and Tools, we go beyond conventional machining by offering a range of special processes that enhance the functionality, precision, and finish of components

✅ Hardening & Heat Treatment (via partner facility)

We coordinate precise heat treatment processes to improve material strength, wear resistance, and hardness for demanding applications.

Processes include: Case hardening, through hardening, stress relieving, annealing, tempering Standards followed: IS, DIN, ASTM

✅ Precision Honing & Lapping

We achieve ultra-fine finishes and precise dimensional tolerances on cylindrical bores or flat surfaces.

Ideal for: Hydraulic cylinders, valve bodies, sleeves

✅ Boring & Internal Grooving (Fine Machining)

For critical tolerances and smooth internal surfaces in high-performance parts.

Used in: Automotive and Aerospace fitments

✅ Custom Keyway Broaching / Slotting

We deliver accurate internal slots and keyways in shafts and bores with strict concentricity and alignment.

✅ Fine Surface Finishing (Ra controlled)

We offer custom surface finishing options to meet your part’s required Ra value for performance and aesthetics.

Common Special Processes

In addition to core machining, we provide several complementary services to deliver complete, ready-to-assemble components:

✅ Heat Treatment

Enhances material hardness, strength, and durability.

✅Surface Treatments

Includes anodizing, plating, black oxide, and phosphate coating to improve corrosion resistance and surface finish.

✅ Non-Destructive Testing (NDT)

Ensures internal soundness and integrity of components using ultrasonic, dye penetrant, or magnetic particle inspection.

✅Shot Blasting / Deburring

Improves surface texture, removes sharp edges, and prepares parts for finishing.

✅ Welding (TIG/MIG)

Protective and aesthetic coatings for industrial components.

✅ Passivation & Electropolishing

Enhances corrosion resistance and surface smoothness, especially for stainless steel parts.

All special processes are carried out in collaboration with certified vendors and undergo strict quality control, documentation, and traceability to meet customer specifications and international standards.

Assembly Services

At Srinivasa Machines and Tools, we offer precision mechanical assembly and sub-assembly services to provide complete, ready-to-use solutions to our customers

✅ Mechanical Sub-Assembly )

We assemble machined components with fasteners, pins, circlips, washers, seals, and bearings based on assembly drawings or customer BOMs.

Examples: Gear housings, shaft + bearing units, valve bodies, fixture assemblies

✅ Press Fitting & Shrink Fitting

Using hydraulic or arbor presses and controlled heating methods, we achieve interference fits with high precision.Used in: Bushes, dowels, bearings, pulley systems

✅ Thread Locking & Fastening

Torque-controlled tightening with thread-lock adhesives for vibration-prone assemblies.

✅ Greasing, Lubrication & Seal Fitting

Proper application of lubricants or greases as per OEM specifications during assembly.

✅ Functional Testing (on request)

For select assemblies, we offer dimensional, movement, or fitment testing to verify proper operation before dispatch.

Address List

- K-10, Saki Vihar Road, Ansa Industrial Estate, Chandivali, Saki Naka, Mumbai, Maharashtra – 400072

- +91 74001 13732

- srinivasamachinesandtools@gmail.com contact@srinivasamachinesandtools.com

Social Networks

- Srinivasa machines and tools

- Srinivasa machines and tools

- Srinivasa machines and tools

- Srinivasa machines and tools

- Srinivasa machines and tools

Srinivasa machines and tools

Crafted With Experience, Built To Last!