About Us

Precision Engineering & Trusted Partnerships

Welcome to Srinivasa Machines and Tools, your trusted partner in precision engineering, machining, and high-quality manufacturing solutions..

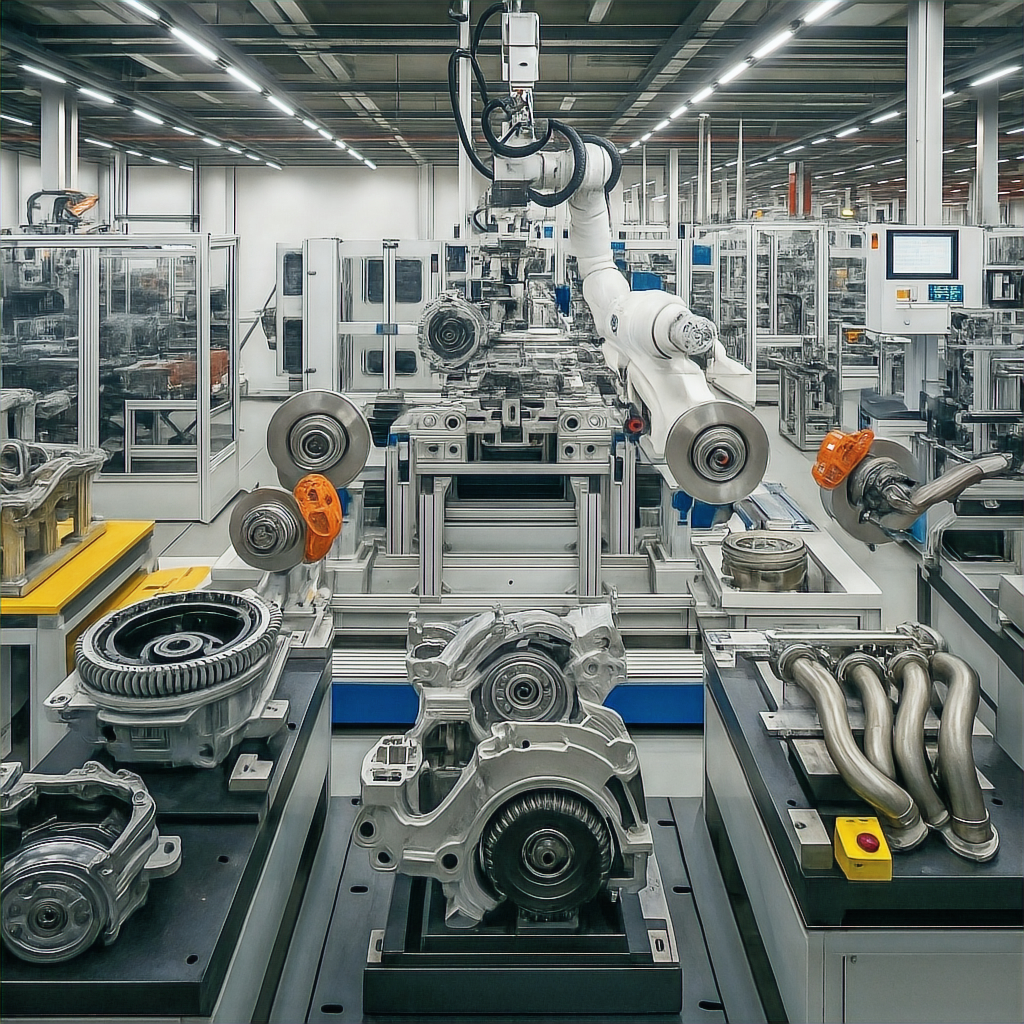

Founded in 2017, Srinivasa Machines and Tools has established itself as a reliable name in precision CNC and VMC machining, serving mission-critical needs across diverse industries such as aerospace, defense, automotive, railways, marine, oil & gas, earthmoving machinery, and renewable energy.

Who We Are

Driven by a passion for quality, innovation, and customer satisfaction, we are an ISO 9001:2015 certified company equipped with state-of-the-art machinery and a skilled workforce capable of executing even the most complex machining projects with speed and precision.Whether you’re developing a prototype or scaling for bulk manufacturing, we offer agile solutions, quick turnaround times, and unwavering adherence to international quality standards.

WHAT WE DO

Precision That Drives Innovation

Whether you're scaling production or innovating a prototype, Srinivasa Machines and Tools brings the quality, speed, and expertise your business deserves.

Advanced Machining Solutions

High-Quality Component Manufacturing

Precision Analysis & Quality Control

From Prototype to Production

SERVICES

Industries We Serve

At Srinivasa Machines and Tools, we proudly serve a wide spectrum of industries that demand high-precision engineering, robust quality standards, and consistent performance. Our CNC, VMC, and toolroom capabilities—backed by ISO 9001:2015 certification—enable us to deliver mission-critical components across the following sectors:

Aerospace

We manufacture high-precision components for commercial and defense aviation. From structural parts to high-tolerance brackets, our aerospace-grade machining supports OEMs and Tier-1 suppliers with reliable and traceable manufacturing solutions.

Defense

We deliver durable, mission-critical components for land, marine, and aerospace defense systems. With stringent quality control and full traceability, we help safeguard national defense operations with parts that meet military-grade specifications.

Automotive

From engine blocks to suspension and braking components in the automotive industry, we serve the automotive sector with batch and custom precision parts that meet high-performance and durability requirements across OEM and Tier-1 supply chains.

Our Capabilities

We combine advanced machining technology, skilled technicians, and robust quality systems to deliver complex components with precision and consistency.

01

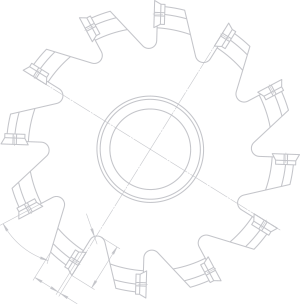

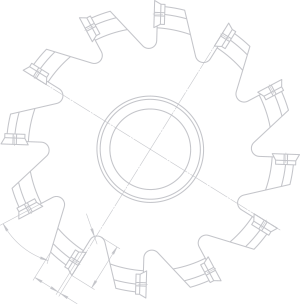

CNC Machining

- High-speed multi-axis turning & milling

- Tight tolerance precision components

- Compatible with a wide range of materials

02

VMC Machining

- 3-axis and 4-axis vertical machining centers

- Ideal for complex shapes and high-volume production

- Superior surface finish and repeatability

03

Material Handling Expertise

- Expertise in machining aluminum, stainless steel, carbon steel, titanium, brass, and engineering plastics

- Support for exotic and aerospace-grade materials

04

Quality Control

- ISO 9001:2015 certified processes

- CMM, digital micrometers, and inspection tools

- In-process and final quality audits

05

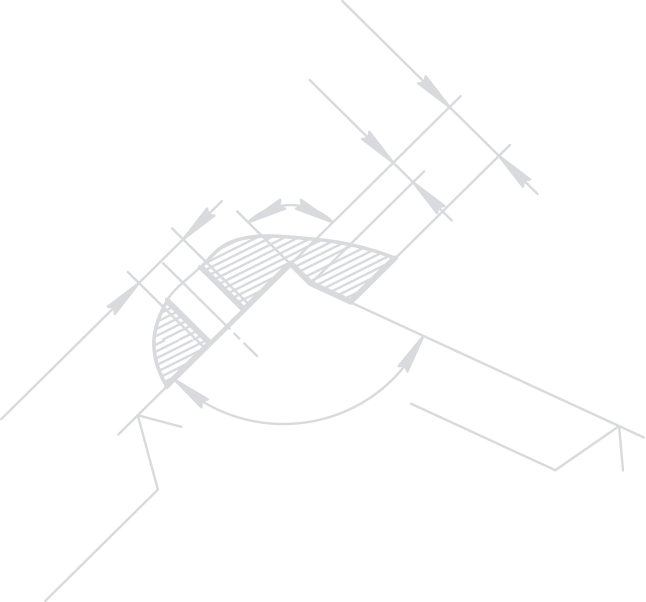

Prototyping & Product Development

- Quick turnaround on sample parts

- Design-for-manufacturing (DFM) support

- Feasibility and tolerance validation

.

06

Reverse Engineering

- Accurate recreation from samples or drawings

- Optimized design outputs for better efficiency and cost

.

Services

Our full-cycle engineering services are designed to reduce your lead times, ensure reliability, and deliver performance across every engagement.

Precision Machining Services

Custom CNC and VMC parts manufactured to exact client specifications, with high dimensional accuracy and excellent repeatability

Fabrication & Assembly

Full-service fabrication, sub-assembly, and mechanical integration for OEMs and equipment builders.

Engineering & Design Assistance

Value-added services such as design improvement, 3D modeling, tolerance stack-up analysis, and manufacturability consulting.

Surface Finishing

In-house and outsourced finishing capabilities including powder coating, anodizing, passivation, polishing, and heat treatment.

Rapid Prototyping

Fast, efficient prototyping of functional components for testing and pre-production validation.

Packaging & Global Logistics

Safe, durable packaging and export-ready logistics management for domestic and international delivery.

Why Choose Srinivasa Machines and Tools?

t.

Let’s Build Precision Together

At Srinivasa Machines and Tools, innovation meets craftsmanship. We believe in building long-term partnerships grounded in

- Trust

- Reliability

- Performance

Explore how we can support your next engineering or manufacturing project with our world-class machining services.

📞 Contact us today to discuss your custom machining requirements.

Srinivasa Machines And Tools

Crafted With Experience, Built To Last!

Follow Us On

- K-10, Saki Vihar Road, Ansa Industrial Estate, Chandivali, Saki Naka, Mumbai, Maharashtra – 400072

- +91 74001 13732

- srinivasamachinesandtools@gmail.com contact@srinivasamachinesandtools.com